NavList:

A Community Devoted to the Preservation and Practice of Celestial Navigation and Other Methods of Traditional Wayfinding

From: David Pike

Date: 2024 Mar 6, 01:56 -0800

Matus Tejiscak et al

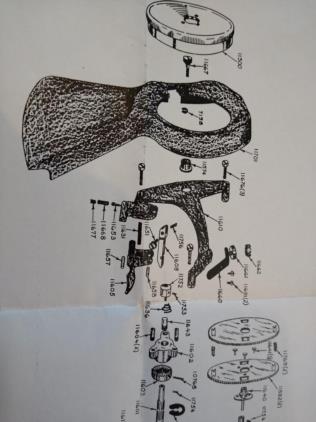

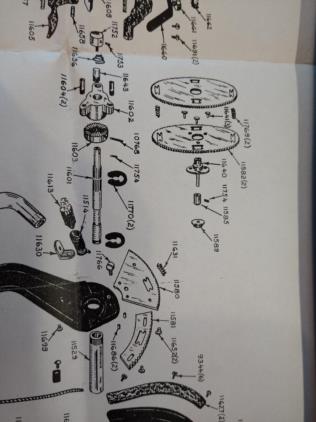

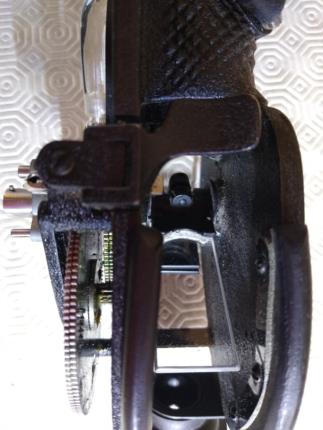

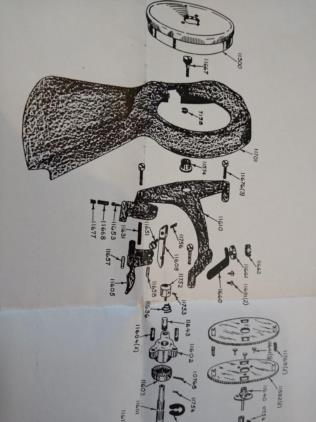

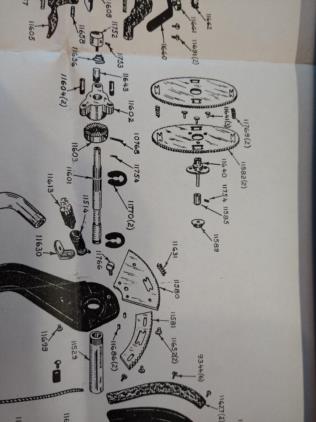

I thought it might be worth indicating the clever method the Link Company used to reduce backlash errors in the A-12 sextant. Where spur gears meshed together, instead of using one thicker wheel for the larger gear, they used two thin wheels sitting on top of each other and held apart in the rotational sense by a pair of tiny compression springs. These springs made sure the teeth on the big wheel made good contact with the teeth on the tiny brass pinion spur gear that was trying to turn the big wheel (See photographs). Contact was then instantaneous whether you pushed or pulled the white plastic thumb drum.

However, the A12 was designed to be built quickly and in great quantity to serve the rapidly increasing volume of trans-ocean air activity. I doubt that anyone imagined that enthusiasts might still be using them 80 years later. The pushing apart of the thin gears will in itself produce wear in the pinion. Also, over the years, the thickening of any oil between the two thin spur wheels might cause them to stick together, so the compression springs are no longer strong enough to hold the teeth apart. Short of a full strip-down, I wonder if it might be worth a quick flush between the big wheels with penetrating oil.

Finally, there’s a ‘gold star’ for the first person to guess how the illustrator achieved the mottled effect on the A12 frame castings in the working drawings.

DaveP