NavList:

A Community Devoted to the Preservation and Practice of Celestial Navigation and Other Methods of Traditional Wayfinding

From: Rafael C. Caruso

Date: 2023 May 29, 07:22 -0700

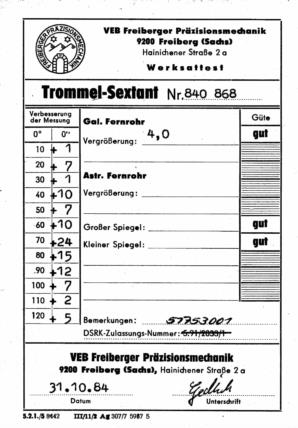

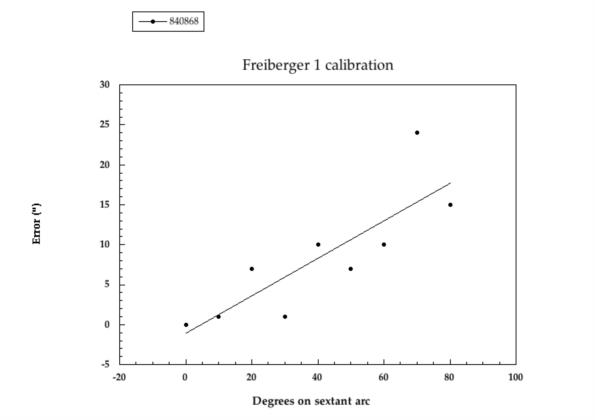

At first sight, I was quite impressed with the linearity of the arc of this old vernier sextant, which I thought implied superb precision mechanics in its manufacture. As Frank Reed wrote: “Apart from one little bump, which may have been an error in the calibration process instead of the sextant, it's almost perfectly linear”. In comparison, a Freiberger drum sextant I acquired a few years ago seems to have a more "nonlinear" arc. The calibration certificate and a plot of the values are attached. I assume these values were obtained by placing the sextant on an optical bench, and measuring the difference betwee nominal values and measured values, for index arm positions at 10° increments. These differences are far less predictable or systematic than those of the Russian sextant, even if they do trend up with increasing index arm angle. Instead, deviations from a straight line seem to be the result of random machining error.

My admiration for the manufacturer of this sextant was a little dampened when I read what Lars Bergman wrote: “The parameters R and E are determined from two angle measurements that are compared with their true values; then the table for every ten degrees is computed.” If the calibration method involves only two measurements on the arc, then, by definition, the line joining these two data points is a straight line. Also, the intereesting reference posted by Modris Fresters ensures a systematic and precisely predictable increase in error with increasing angle. If this is the case, the “perfect linearity” of the sextant arc isn’t a consequence of its precision machining, but a result of the approach use to construct its calibration table. This approach seems quite different from the one I assume was used by Freiberger Precision Mechanics, or by other manufacturers that provide actual values.

Best, Rafael C