NavList:

A Community Devoted to the Preservation and Practice of Celestial Navigation and Other Methods of Traditional Wayfinding

Re: Bygrave and MHR-1 locking mechanism construction

From: Wolfgang Hasper

Date: 2009 Oct 1, 20:19 +0200

From: Wolfgang Hasper

Date: 2009 Oct 1, 20:19 +0200

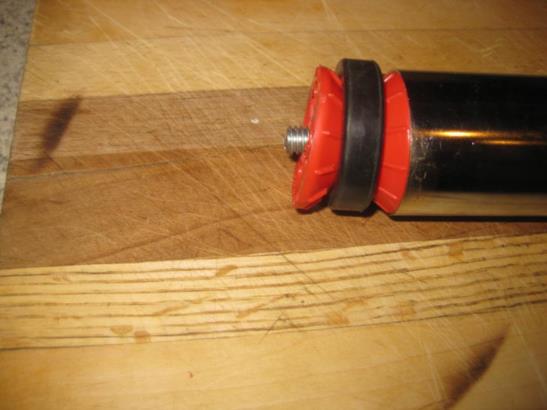

Gary, thank you for your reply to my earlier question and those most interesting experiments. I am courious to learn about your results: Does the tightening torque affect the alignment, is a 90� turn sufficient..? I myself will shortly start some experiments on tube-making to custom diameters which -given the results were positve- might solve that cumbersome problem. My idea is to use a bending apparatus to bend pieces of various materials to form my own tubes. This should be possible with sheet metal the seam then soldered/brazed/welded, plasic (in heated state) with the advantages of low weight, no corrrosion, cheap price, easy to glue and possibly even with cardboard. I have a printer that is ready to print on cardboard up to 1 mm thickness. Maybe it is even possible to first print/engrave scales onto flat (plastic) material and then bend it... Should that work it seems promising to use this http://www.gravograph.com/english/engraving-products/gravoply_ultra.php Since it can be laser-engraved any design could be realised easily. THe experiments will take some time, just too busy right now. I will report as soon as results are ready. Wolfgang Am Mittwoch, 30. September 2009 03:55 schrieb glapook@pacbell.net: > In the past we have discussed the superiority of the MHR-1 to the Bygrave > due to its mechanism for locking the two tubes together to prevent unwanted > movement while resetting the cursor. See prior posts: > > http://www.navlist.net?i=109049&y=200907 > > > http://www.navlist.net?i=109054&y=200907 > > > > I have made several copies of the Bygrave using as its base a 1.500 O.D. > standard sink "tail pipe" or drain pipe twelve inches long on which to > mount the cotan scale. See my prior post on this: > > http://www.navlist.net?i=108949&y=200907 > > > I have also suggested in the past that a three and a half buck off the > shelf "test plug" might be the basis for a locking mechanism, see: > > > http://www.navlist.net?i=109056&y=200907 > > The problem with making a copy of the Bygrave or the MHR-1 is finding tubes > that are close enough in size to provide the proper sliding fit. My cotan > scale is printed on paper and wrapped around the 1.500 inch O.D tube and > then covered with a clear plastic sheet expanding the diameter to 1.520 > inches. I measured the I.D of standard one and a half inch PVC pipe and > found it is 1.566 which is a good fit and within the range of adjustment of > the "test plug." So today I decided to give it a try. I purchased a piece > of such pipe, a piece of 5/16th inch threaded rod, a 5/16 inch nut, a > 5/16th inch self locking nut, and another test plug, about ten bucks. The > original bolts in the test plugs are 5/16ths. > > > The attached pictures shows the process. Disassemble the two test plugs and > use the two smaller plastic pieces, one of the large pieces, one of the > rubber rings one of the washers, and one of the wing nuts. The other pieces > are not used. The small plastic pieces are designed to use carriage bolts > so have square sockets for the heads of the carriage bolts. Modify one of > the small plastic pieces by opening up the square socket to allow the use > of a normal hex nut (or modify a nut to fit in the existing square socket.) > Tilt the unmodified small plastic piece and you can insert it into the end > of the cotan tube. Straighten it out and position it so it protrudes from > the end of the cotan tube. Cut a piece of one inch PVC pipe a little bit > shorter than the cotan tube and put it inside the cotan tube. This is to > prevent the plastic piece from being drawn into the tube under tension. Cut > the threaded rod so that it will go through the tube and protrude out the > end. Put the wing nut on the rod and place the self locking nut on the rod > and twist them together to lock them solidly to the rod, "double nutted." > Place the rod though the washer and then through the large plastic piece > and slide this whole assembly through the tubes so that the rod protrudes > from the other end. Place the rubber ring on the rod followed by the > modified small plastic piece and a regular nut. Turn the rod using the wing > nut to tighten up the whole thing. Now slide the one and a half inch PVC > pipe over the assembly, tighten the rod and it locks the two tubes > together. > > I have not yet made the cosine scale to go on the one and a half PVC pipe > but that should not be a problem. I plan on making the same type of cursor > using clear plastic sheet. The only thing I don't like about this is the > PVC pipe has a thick cross section and I will continue to look for a > thinner piece of tubing with the same I.D. to eliminate the parallax > problem with the cursor so far away from the cotan scale. > > > gl > > > > > > > > > > > > > > > > > > > > > > -- Wolfgang Hasper Beckstra�e 87 64287 Darmstadt 06151-4289333 --~--~---------~--~----~------------~-------~--~----~ NavList message boards: www.navlist.net Or post by email to: NavList@navlist.net To , email NavList-@navlist.net -~----------~----~----~----~------~----~------~--~---