NavList:

A Community Devoted to the Preservation and Practice of Celestial Navigation and Other Methods of Traditional Wayfinding

From: Paul Dolkas

Date: 2016 Oct 13, 21:51 -0700

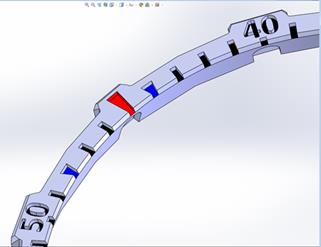

I’m coming in late to this conversation, but you most emphatically CAN use 3-D printing to do engraving of scales. It all depends on how fine you want the marks and how small you need the numbers. The outer watch bezel I made a few years ago in silver in an example of how it can be done. You make depressions in the CAD model, (“Cuts” in SolidWorks parlance) and these are then filled in with paint and the top surface sanded lightly to remove excess:

At the time I made this bezel, the smallest a depression in silver could be was about 0.4 mm. So I made the marks 0.5mm wide x 0.4mm deep by 1 or 2 mm long. Similarly, the number characters are each about 2mm tall x 0.5mm deep.

There are much higher definition plastics available now (much cheaper than silver as well) that can take that down to 0.1 mm. That’s .004”, which is pretty fine. Here’s a link to the design rules page for Shapeways: http://www.shapeways.com/materials/high-definition-acrylate

A potential problem with all 3-D printed processes is that some of the materials shrink during the manufacturing process. I went through a few iterations before I realized silver parts shrink 1%. I don’t think they publish these numbers, so you would have to try a test part to find out. Of course, if everything is made of the same material, it all shrinks equally, and so it’s irrelevant for a slide rule type of thing.

Hope this helps.

Paul Dolkas

From: NavList@navlist.net [mailto:NavList@navlist.net] On Behalf Of Bob Goethe

Sent: Thursday, October 13, 2016 8:29 AM

To: paul@dolkas.net

Subject: [NavList] Re: Traditional navigation by slide rule

>>3D printing might be marginally useful for the bulk sliding parts, but it would not do all that well with engraved scales<<

This is the same word I got also from a salesman at MakerBot. He said that year 2016 was still relatively early days in terms of 3-D printing, and that the process was not yet up to the challenge of the kind of slide rule project I was describing to him.

>>the Pickett route.... the PCB route....<<

These suggestions are like gold to me, Peter. Thank you!! I have been a little stuck on the very basic issue of fabrication, but you have given me new avenues to explore.

Bob