NavList:

A Community Devoted to the Preservation and Practice of Celestial Navigation and Other Methods of Traditional Wayfinding

HR-1 working re-creation

From: UNK

Date: 2010 Jan 18, 03:59 -0800

From: UNK

Date: 2010 Jan 18, 03:59 -0800

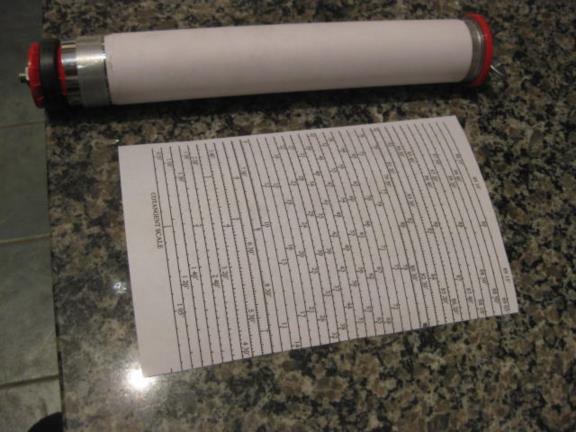

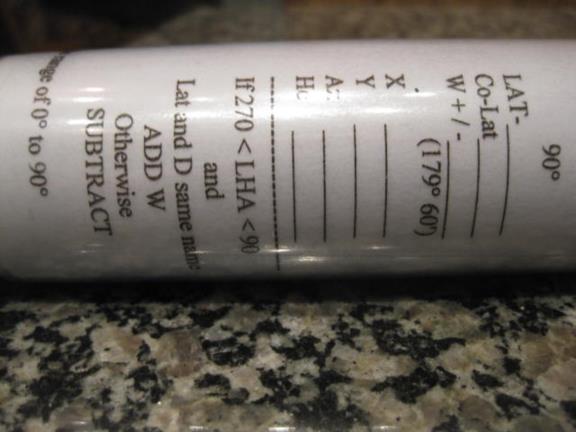

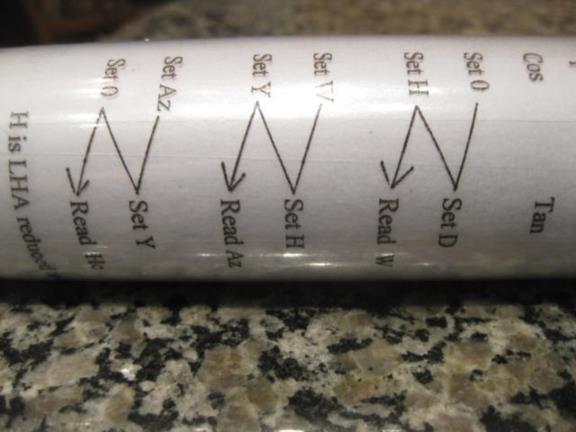

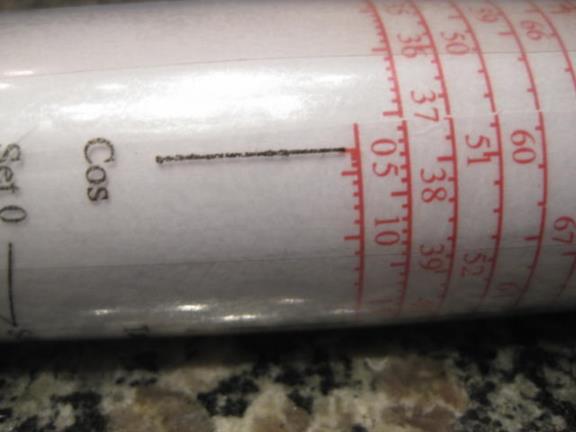

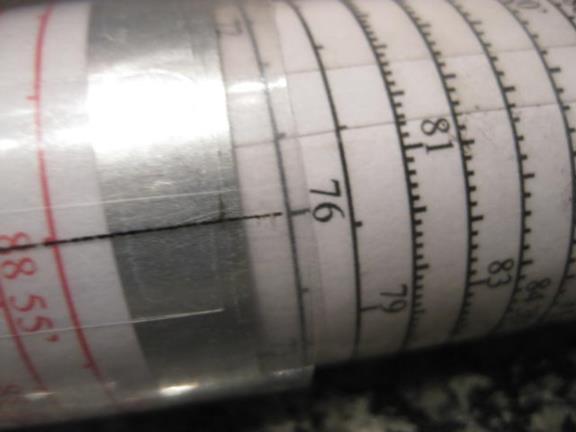

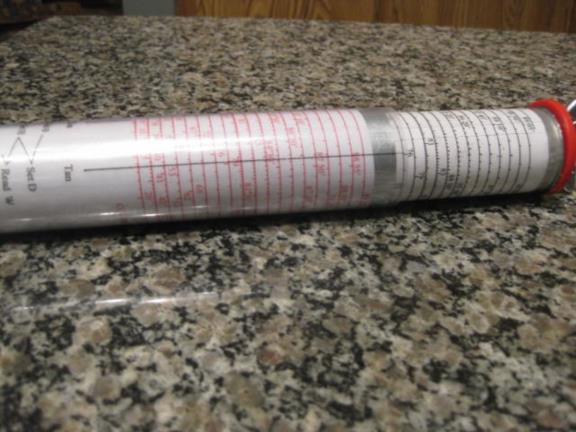

I wrote back in July about my plan to make a working model of the HR-1 German model of the Bygrave slide rule using off-the-shelf items to make the locking device that sets the HR-1 apart from the Bygrave. See my prior posts at: http://www.navlist.net?i=109056&y=200907 http://www.navlist.net?i=109993&y=200909 I have now accomplished my goal. I have attached twenty eight photographs showing how to do this, but read my prior posts before going further. Going in numerical order, the first two photos show the 1.500 inch outside diameter tube that I have used for my prior Bygrave re-creations cut off to ten inches that will be used to mount the cotangent scale. The next photo shows the locking mechanism I had described in my prior posts along with the cotangent tube and a piece of PVC pipe cut to fit inside the cotangent tube to take the compression load of the locking mechanism. Photo four shows the locking mechanism with the PVC pipe in the assembled position. Photos five, six and seven show the same now installed inside the cotangent tube. Photo eight shows a detail of the expanding ring that is used to lock the two tubes together. The difficulty in making this is finding tubes that are a good tight fit. I found aluminum tubing used for making antennas at: http://www.dxengineering.com/Products.asp?ID=278&SecID=136&DeptID=43 They have tubing with an outside diameter of 1.625 inches and a wall thickness of .058 inches making the internal diameter 1.519 inches, a good fit on 1.500 inch O.D. tubing. If you could print the cotangent scale directly on the 1.500 tube this would be a good solution but my method requires me to print the scale on paper and mount it on the tube under a plastic sheet for protection making the diameter of the cotangent scale 1.520 inches, too large to fit inside a tube of this size. The next largest size of tubing in 1.75 O.D., 1.634 I.D., too large for a good fit on the 1.520 diameter cotangent scale. http://www.dxengineering.com/Parts.asp?ID=2413&PLID=278&SecID=136&DeptID=43&PartNo=DXE-AT1251 Photo nine shows this tubing in line with the cotangent tube. Photo ten shows my solution to this problem. I decided to bush the inner tube out to fit closely to the cosine, outer, tube. I used five sheets of regular paper, 8.5 by 11 inches (standard paper size in the U.S.), glued with rubber cement (which has the advantage, that if you need to start over, the glue will come off easily) totaling 55 inches wrapped around the tube. The paper is .004 inches thick and the five sheets brought the diameter close enough (considering that the cotangent scale and the plastic sheet would be placed around it) to make a good fit to the cosine tube. Since I wanted to seal the scale from the environment, prior to putting the paper on the tube, I used several sheets of the sticky plastic sheets cut into 1/4 inch wide strips to wrap around the tube near the top to bring the diameter out far enough that the plastic sheet mounted on top of the scale would stick to these layers of plastic thus sealing off the top of the tube and the scale. After mounting the paper I did the same thing at the other end of the paper this time using 3/4 inch wide strips. Photo eleven shows the cotangent scale and photo twelve, thirteen and fourteen shows th scale mounted on top of the paper on the cotangent tube and covered with the protective plastic sheet. Photos fifteen and sixteen show the cosine scale mounted on the larger tube and covered with a plastic sheet. Photos seventeen and eighteen show the cotangent tube being inserted inside the cosine tube. Making the cosine scale presented a bit of a problem. Since the cosine tube has an O.D of 1.750 and the cotangent scale was only 1.520 inches in diameter it was necessary to print the cosine scale at a larger scale than the cotangent scale which was not a problem using Acrobat. However when I tried out the scales a problem presented itself. My printer made the cosine scale wider but also taller so that the pitch of the scales no longer matched. Although it worked this way it caused ambiguity since the cursor would sometimes end up between spirals on the cotangent scale and either answer (higher or lower than the end of the cursor) could have been the correct one. I contacted Dave Walden (the original source for the scales I have been using) and he was able to modify the vertical and horizontal ratios of the cosine scale so that, when printed out wide enough to fit around the tube, the vertical spiral pitch matched the cotangent scale. (Thanks again Dave.) Photos nineteen and twenty show the two cursors, the cosine cursor pointing to zero and the cotangent cursor on 76 degrees. I again made the cursor out of clear plastic by first printing the instructions on a sheet of paper, drawing in the cursors and then photocopying this onto a clear plastic sheet made for use in an ink jet printer. I then wrapped it tightly around the cosine scale and held in that position with two pieces of scotch tape on the inside of the cursor tube. I then wrapped a sticky clear plastic sheet around it to protect the printing on the cursor tube and to hold it in shape. I then removed the scotch tape. Photo twenty-one shows the condensed instructions printed on the cursor tube. The cosine scale is white underneath this section of the cursor tube to enable easier reading of the instructions. Photo twenty-two shows the "zig-zag" printed on the cursor tube which lines up with the two cursors to guide the user through the computation. Photo twenty-three and twenty-four show close ups of the cursors pointing to zero on the cosine scale and 76° on the cotangent scale. Photo twenty-five shows the cursor pointing to 76°on the cotangent scale. Photo twenty-six shows the tubes extended so that the cotangent cursor can point at 55'. Photo twenty-seven shows a close up of the cursor pointing to 55' at the bottom of the cotangent scale. Photo twenty-eight shows the tubes collapsed. Turning the wing-nut (control knob) one quarter of a turn locks the two tubes together and is an easy manipulation to make. Since the cosine tubing is only .058 inches thick the cosine scale and the cotangent scale are very close together, and to the cursor, minimizing any parallax problem when reading the scales. I have also attached the modified cosine scale and note that the tick marks go down from the line under the numbers. The cotangent scale is made with the scales posted last March bt Dave Walden for the flat Bygrave at https://navlist.net/img/107501.f2-lapook1.pdf Also attached is the form for the cursor tube. The only downside to this model, compared to the prior model I made of the Bygrave, is that it is three times heavier since the locking mechanism and the cosine tube each weigh as much as my original re-creation of the Bygrave. I demonstrated this HR-1 to Frank, Mike and Greg prior to our flight last Saturday. gl